3D printing technology adoption among companies and entrepreneurs is low due to the lack of awareness on printer construction and maintenance, which cause them to fear that these machines are expensive to own.

They also have the perception that the 3D printers available in the market today have parts that are not suitable for robust application.

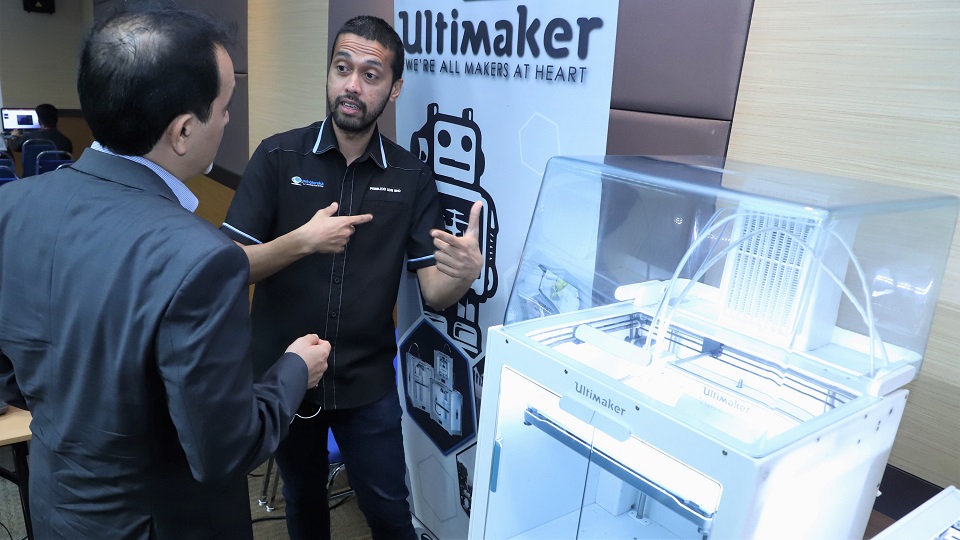

On 28 Nov, MIMOS conducted a 3D Printing Technology and Product Design Tech Talk as part of initiatives to foster Industry 4.0 adoption towards high value-added skillsets development.

Led by Product Design & Digital Modelling team, participants were shown the ways to build a scalable 3D printer that can cater for large-size components and the various industrial applications and processes to enhance robustness.

The programme enabled participants to emulate proven process of product design towards supporting Industry 4.0 adoption.

3D printing patent expired in 2009. As a result, 3D technology and printing material have become affordable. In Malaysia, this will take 3D printing further into segments such as making artificial human limbs and organs, creative arts and collectible items – apart from heavier industrial applications such as in automotive, architecture and engineering.

For further information on future similar training programme, organisations can contact MIMOS at +603-8995 5000 ext 5279 (Fara) or email to faradaya.machmud@mimos.my