Overview

A pristine graphene material on 8-inch (200mm) wafer for enabling the manufacturing and development of next generation high performance electronics.

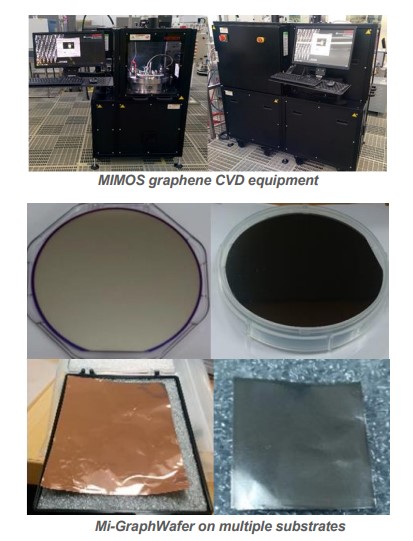

MIMOS Mi-GraphWafer is a state-of-the-art process technology for the development of pristine Graphene on 8-inch (200mm) wafer to enable the manufacturing and production of next generation advanced electronics. The graphene layer developed are available at the highest purity as well as uniformly-synthesised through industry-grade chemical vapour deposition (CVD) process technology.

Technology Summary

Mi-GraphWafer

State-of-the-art process technology for the development of pristine Graphene on 8-inch (200mm) wafer to enable the manufacturing and production of next generation advanced electronics.

Industries: E&E industries, SMEs, Government

Features

- High purity

- Uniform

- Large area

- Customisable

Technology Benefits

- Pristine graphene material

- Scalability

- Enabling new nanomaterials development

Mi-GraphWafer comprises the following features:

Features

Mi-GraphWafer comprises the following features:

- High Purity

Pristine single layer graphene synthesised through chemical vapour deposition (CVD) method on wafer. Can be tuned for biand multi-layer graphene. - Uniform

Single layer graphene coverage >90%. Top and bottom heater for uniformly-controlled growth and coverage. - Large Area

Can be synthesised on substrate of up to 8” (200mm). Also accept small sample size. - Customisable

Can be tuned and structured based on requirements and applications.

Technology Benefits

The main impacts of Mi-GraphWafer are:

- Pristine Graphene Material

High purity single layer graphene that can be transferred and utilised as a nanomaterial by itself for R&D and device development purposes. Quality of graphene controlled at a consistent and uniform manner across the substrate. - Scalability

Process capability-ready. Structuring and patterning of graphene material can be executed on full wafer-scale level for device development. - Enabling New Nanomaterials Development

Functionalisation of base graphene material can be achieved through multiple process add-ons for value-added purposes. Matured industry-grade chemical vapour deposition process

technology utilised.