Overview

Machine Vision-Based Inline Quality Control (QC) is an automated machine learning-based vision inspection system. For manufacturing lines, vision inspection system is one of the critical QC tools. It is implemented to screen out defective components and parts to ensure good product quality.

The platform automatically detects complex defects that may not be addressed by traditional machine vision methods.

Machine Vision-Based Inline Quality Control (QC) provides image analytics and complex defect detection capabilities for inline QC inspection in the manufacturing industry

Features

Machine Vision-Based Inline QC provides the following features:

- Defect Classification

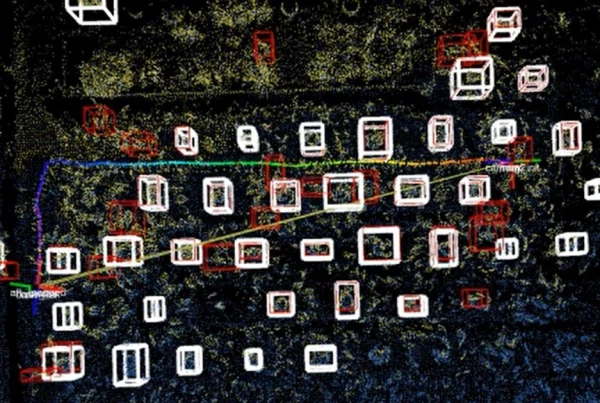

Real-time quality inspection with an AI-based classification model to determine complex and irregular defects. - Defect Detection and Analysis

Real-time quality inspection with an AI-based defect detection to detect defect properties such as location, size and type on visible and non-visible light images. - Annotation and Training Tool

The platform comes equipped with capabilities for annotation, model training, evaluation and reporting.

- Third Party Automated Optical Inspection (AOI)

An interface is provided for third party system integration.

Technology Benefits

The main impacts of Machine Vision-Based Inline QC are:

- Machine Learning Defect Detection Algorithm

The machine learning algorithm is customised to generate predictive models. This allows defect classification and detection on complex defects that may not be addressed by classic rule-based algorithms

- Model Training Visualisation and Reporting

The platform provides customised model training and evaluation with visualisation and reporting..